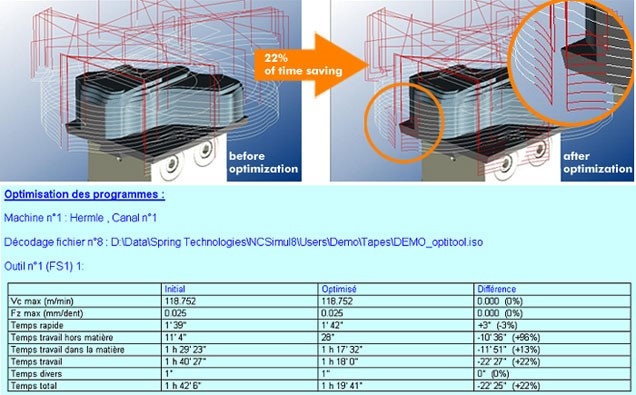

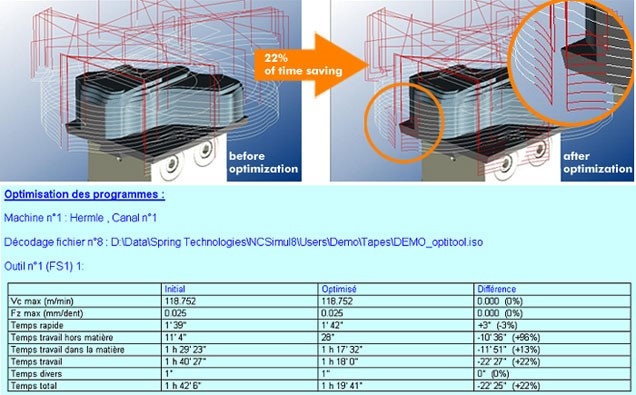

OPTITOOL analyzes cutting conditions, dramatically reduces “air cutting,” optimizes feed rates, and allows users to create better cutting strategies. The sum benefits are a reduction in the production cycle times, enhancement of cutting operations, and fast development of new G-code files for future applications.

This NCSIMUL Machine module allows you to optimize the tool lengths, air cutting and cutting conditions of your NC programs (from 3 to 5 continuous axis).

- Reduce the operating cycle of your programs

- Enhance the quality of your machining operations

Thanks to OPTITOOL, increase the profitability of your machine shop floor!

OPTITOOL special features

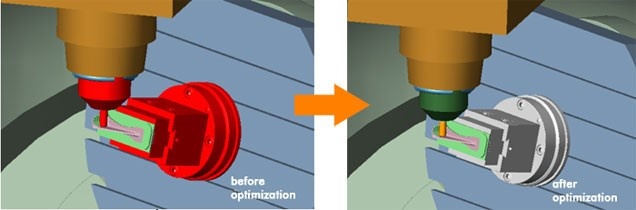

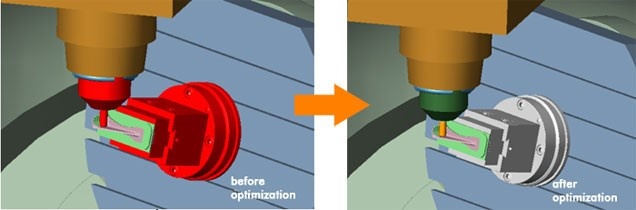

Tool length optimization (NCSIMUL Machine standard feature)

- Reduction of bending phenomena as well as collision risks with the tool support (attachment + extensions)

- Suppression of the collisions with the tool support as well as reduction of the toolbeding

Air cutting optimization

- Thanks to OPTITOOL, the NCSIMUL Machine user can define its own approach and retract motion parameters in order to minimize the air cutting and maximize the use of rapid motion (or working feedrate with high speed).

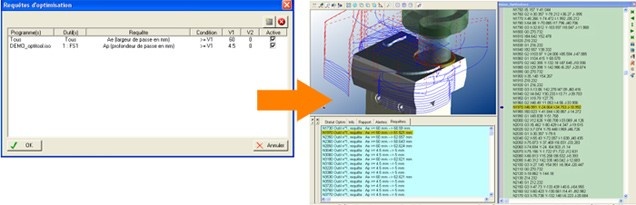

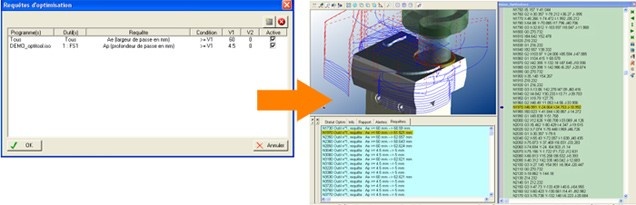

Analysis of cutting conditions for each toolpath section in a block by multi-criteria search

- OPTITOOL features a multi-criteria search function which allows users to analyse one or a set of NC programs for one or several tools in accordance with their cutting parameters. Without requiring any modification in the program, OPTITOOL is able to find the tool trajectory sections (can be set up in function of the tool diameter) that do not match the cutting conditions defined by users.

Cutting condition optimization

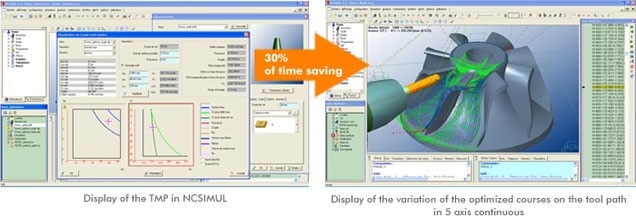

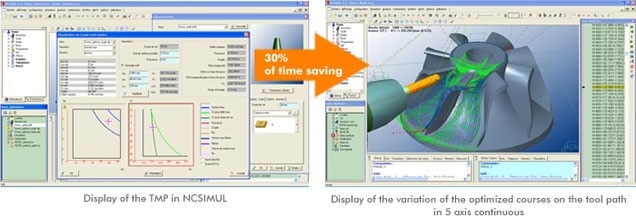

- Built from an innovating technology based on SPRING Technologies' TMP know-how, OPTITOOL incorporates the main TMP used by the industry for the past 20 years in the form of working zones.

- NCSIMUL Machine users have the choice to optimize the cutting conditions (feedrate and rotation speeds) in function of the required machining depth and width (Ap, Ae) and of the strategy beforehand defined (tool life, maximum feedrate, roughness, etc.)

OPTITOOL also allows users to save their own TMP according to the experience acquired in the workshop and thus, optimizing their NC programs by integrating the company know-how

Source SPRING Technologies